Semiconductor Equipment & Materials

Wafer Fabrication – Thin Film and Advanced Packaging Process

Wafer Processing Systems

• Fully automatic wafer backgrind, mounting and de-tape system for 300mm ultra-thin wafer

• Stand alone Mounter, Detaper, Laminator of BSP/LC Tape, DAF Tape, BG & Dry Film

• UV irradiation, Manual Tape mount, De-tape, OCR Barcode print

• Wafer Transfer System, Debonder, Warpage Adjuster for eWLB process

For more information, please visit www.dynatech.co.kr.

DWL 2000 GS / DWL 4000 GS

The most advanced industrial grayscale lithography tool on the market.

• Fast and flexible high-resolution pattern generators.

• Optimized for industrial-level Grayscale Lithography

• Designed for high-throughput patterning of masks and wafers

• For integrated circuits, MEMS, micro-optic and microfluidic devices, sensors, holograms, and security features on banknotes and ID cards.

• Patterning of complex 2.5D structures in thick photoresist over large areas.

• Suitable for wafer-level micro-optics used for telecommunications, illumination, and industrial display manufacturing, as well as for device fabrication in life sciences.

For more information, please click here.

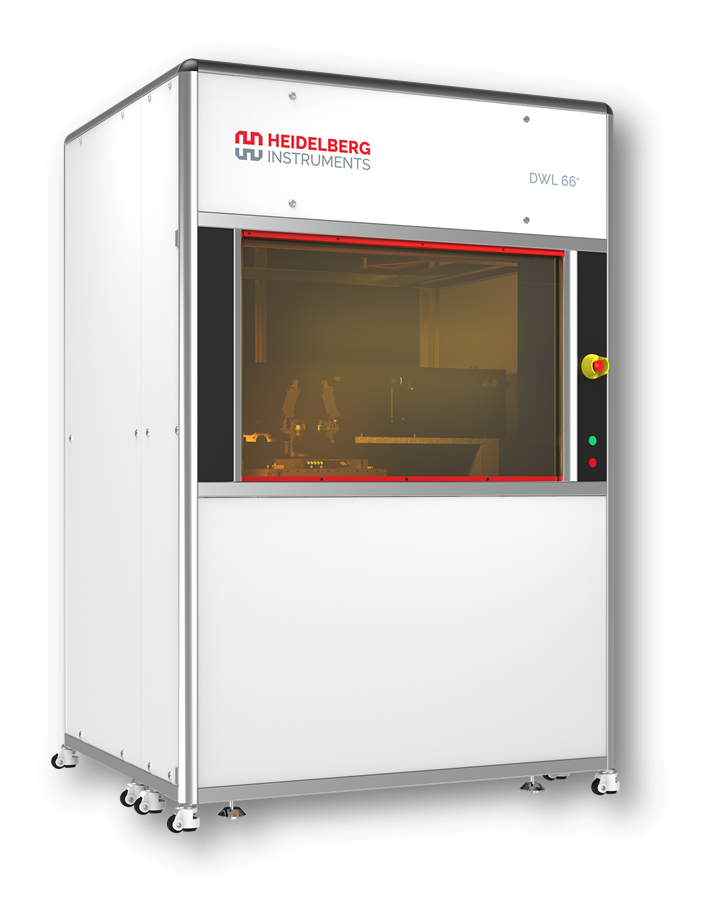

DWL 66⁺

Most versatile system for research and prototyping with variable resolution and wide selection of options.

• High-resolution direct-write pattern generator.

• Choice of 6 write modes with 2 laser wavelengths

• Ideal for research and development (R&D) in microelectronics, MEMS, microfluidics, sensors, non-standard substrates, advanced packaging — virtually any academic application that requires microstructure fabrication.

• Stands out with its Grayscale Exposure Mode which creates complex 2.5D microstructures such as micro-optics for mobile applications, diffractive optical elements (DOE), computer-generated holograms, and structured surfaces.

• It is a highly flexible and customizable system that precisely matches the requirements of your applications.

• Key features of the DWL 66⁺ are a high-resolution mode, front- and backside alignment, absolute position calibration and an automatic loading system.

For more information, please click here.

MLA 150

The fastest maskless aligner for R&D, rapid prototyping, and small production volumes.

• State-of-the-art Maskless Aligner Lithography tool.

• Fast automated front- and backside alignment procedures and outstanding speed.

• Areas of application include MEMS, micro-optics, diffractive optical elements, sensors, electronic components, and other devices for materials and life sciences.

For more information, please click here.

MLA 300

Optimized for flexible industrial production with highest precision and seamless integration into industrial production lines.

• High throughput, a simplified workflow, and integration with manufacturing execution systems (MES).

• Used for the production of sensors and sensor ICs, MEMS, and microfluidic devices.

• Full automation with customizable loading options, software designed for production environments, and patented substrate tracking technology.

• Modularity enables fast maintenance, replacement, or repair. Real-time autofocus compensates for substrate warp or corrugations, ensuring flawless patterning.

• High resolutions of 2 µm lines and spaces at the high throughput and high availability expected in production.

• Integration Customizable workflow “wizards” to start exposure jobs, and integration to a central MES via SECS/GEM or OPC-UA protocols.

For more information, please click here.

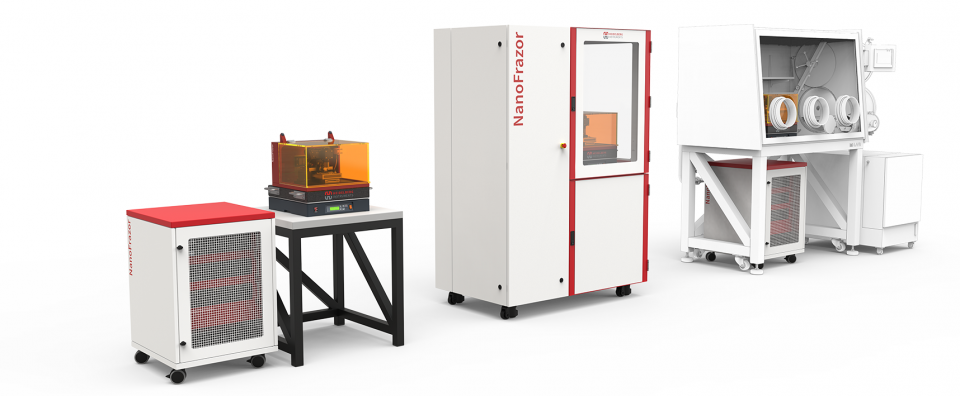

NanoFrazor

The versatile and modular nanolithography tool.

• Groundbreaking commercial system for Thermal Scanning Probe Lithography(t-SPL).

• Easy patterning of nanostructures even with complex geometries; minimum lateral features 15 nm, vertical resolution 2 nm.

• Markerless overlay and stitching accuracy 25 nm specified, sub-10 nm overlay shown.

• Areas of application include Quantum devices, 1D/2D materials, Photonics and Biotechnology.

For more information, please click here.

μMLA

Configurable and compact tabletop maskless aligner.

• State-of-the-art in maskless technology built on the renowned µPG platform.

• Entry-level research and development (R&D) tool for virtually any application requiring microstructures.

• Typical examples are Microfluidics, Micro Optics, Sensors, MEMS, and Material Science.

• Flexible and customizable tool.

For more information, please click here.

For more information, please visit www.heidelberg-instruments.com.

Ohmiker-30

Model Diamond Thermal and Electron Beam Evaporator, high-capacity manufacturing model

Fully automatic with manual override system for 2” to 12” wafer in a compact footprint. The Thermal & Electron Beam Evaporation System is designed for conformal and lift-off deposition process of thin film metal.

Sputter & ICP Equipment

Seker-90P: Optical Coater

Ohmiker-50SL: Sputter

Ohmiker-60B: Evaporator

Batch Type Process Equipment

Batch type process for Dry Film strip, Photoresist Strip, Glass Slim/Etch, Wafer Clean, Electroplating ECD.

Frontend Wafer Fabrication Process Equipment

1. EUV Mask Clean

2. Prime Wafer Clean

3. Wafer Stress Release Etch

For more information, please visit www.gptc.com.tw.

Metrology & Inspection

TREX 630

The TREX 630 series is for 200mm or 300mm wafers and may be configured for lab or in-line use. This system's high-uptime, low maintenance configuration have already been selected by a large majority of the 300mm fabs world wide. This series may be configured a number of ways, from a powerful single sealed tube system to a powerful quad-source sealed tube configuration.

TVD-910

The Technos TVD-910 completely automates the vapor phase decomposition (VPD) prep for wafers. By dissolving the top oxide layer and concentrating the surface, it offers the ultimate in sensitivity for trace metal analysis. This versatile tool can prepare the droplet for analysis by placing it in a vial for inductively coupled mass spectrometry (ICP-MS) or drying the droplet on the surface of the wafer for total reflective X-ray fluorescence (TXRF).

For more information, please visit hha.hitachi-hightech.com/en/.

CMT-SR5000

The CMT-SR5000 is a high precision Four Point Prone system equipped to measure the Sheet Resistance and Resistivity of Silicon Wafer. This system is designed for easy operation by a personal computer with exclusive software, and this software has functions for various data analyses mapping and so on.

For more information, please visit www.fpp.co.kr.

QRA & Materialographic Preparation

For more information please visit www.struers.com.

PM6

The PM6 machine is used extensively in the preparation of:

• Geological Thin Sections: i.e. Rock lapping system

• Semiconductor Materials i.e. Polishing silicon wafers

Tribo CMP System

Logitech’s CMP system offers nanometer level material removal capabilities on either individual die or wafers up to 200mm diameter.

This system is particularly suitable for the following specific applications:

• Silicon wafer CMP to <1nm Ra

• Global CMP of III-V Compound Semiconductor

• Global CMP of brittle, friable IR material substrates

• Global CMP of Sapphire, Gallium Nitride & Silicon Carbide substrates

• Reclamation of EPI ready substrates

• Final Stage thinning of SOS & SOI wafers to below 20 microns

• Device delayering for reverse engineering of FA applications

For more information, please visit www.logitech.uk.com.

For more information, please visit www.probestation.tw.

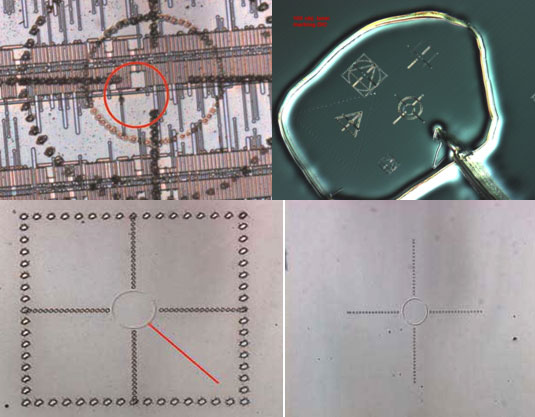

Laser Marking & Patterning System

Navigation marks and/or patterns can be made on top of intermediate levels or on the substrate. This important feature adds another dimension to navigation by providing benchmarks for polishing cross-sections.

Applications:

• Circuit Isolation

• SEM, AFM & FIB Navigation

• Hard Disk / Disk Media

• Height Selective Circuit Isolation on Multilayer Integrated Circuits

• LCD repair

• Marking

• Micro Machining

• Probe Stations

• Removal of Passivation from Integrated Circuits

Specialty Chemicals & Consumables

Specialty Materials

• RDL, Wafer Bump Process Specialty Etchants

Ti, TiW, Cu, Au, NiV, Si, Al, Ni, Cr, SiO2, Si3N4, Rework solutions

• Photoresist Strip or Polymer Removal Material

Positive & Negative Photoresist stripper, Thick Liquid and Dry Films stripper

• Gold Plating Solution

Non-cyanide gold solution, Reclaim service

• Photoresist Material

Positive and Negative. Application for FPD, LED and IC Fabrication.

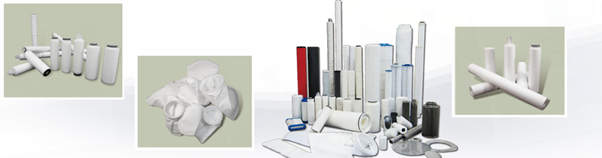

Semiconductor Grade Filtration Solutions

1. Semiconductor grade filtration solution

2. Electronics manufacturing grade filtration solution

3. Medical/pharmaceutical grade filtration solution

4. Food and beverage grade filtration solution

Colloidal Gold

SPI-Mark unconjugated gold colloidal suspensions are of outstanding EM quality.

MICA Sheet

The highest quality for thin film deposition, replication and AFM studies.

Parafilm(R) M

A unique self-sealing, moldable and flexible film for numerous uses in the typical laboratory, including the electron microscope laboratory.

Software

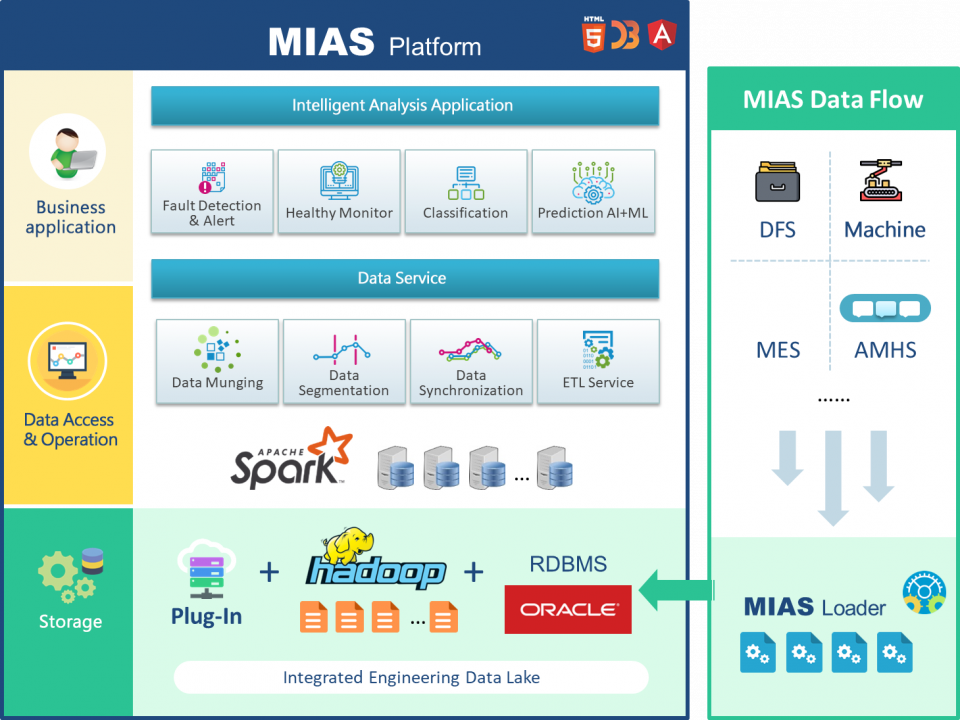

Advanced Yield Enhancement Data Analysis Software

Specializing in

– EDA: Engineering Data Analysis

– SPC: Statistic Process Control

– EEAS: Equipment Engineering Analysis System

– DOE: Design of Experiments

– MIAS(Big Data): Manufacturing Intelligence Analysis System solutions applied for IC, FPD, Solar and other high tech industries.

• Accumulated 100+ successful stories among China and Taiwan high tech industries.

• TYNE is the leading brands of Big Data Analysis software!

2. MES Host

UTI Stepper Parts & Equipment Repair and Exchange

Supports customer in refurbished UT stepper equipment, parts and contract service. Offers a range of specialty materials like Silicon Wafers, Targets/Crucibles and Integrate Small Systems for the semiconductor market.

• For model 990, 1000, 1100, 1500, 1700, 1900 Ultratech steppers

• Available sizes: 3", 4", 5", 6" for round substrates

• Fully refurbished and operational

• Demonstration can be conducted in our facility in Rocklin, Ca.